FAQ

Frequently Asked Questions

Explore this page to find answers to the most commonly asked questions we get. Our aim is to provide you as the consumer with the knowledge you need to make informed decisions about your choice of insulation!

What is R-Value?

R-Value was invented to measure fiberglass insulation. In the late ’50s, when insulation became code to be installed in our homes, fiberglass insulation was the only insulation available. In return, R-Value was established to measure the fiberglass resistance to heat flow.

In order to better explain why R-Value was established for fiberglass, we need to look at the definition of R-Value and the three heat transfers that happen on any building or structure.

The Three Types of Heat Transfer:

- Conductive-transfer of heat flow through any given material.

- Convection-air movement (EPA states 40% of monthly utility bills are contributed to air movement).

- Radiation – rays from the sun.

Fiberglass insulation only reduces one of the three heat transfers- conduction. It does not stop convection or radiation.

Spray foam insulation stops or controls all three of the heat transfers that occur on any building or structure. This is what makes spray foam insulation so effective by saving up to 50% on monthly utility bills, better indoor air quality as well as its ability to never shrink or settle.

Where do you apply spray foam?

Spray foam is installed to the roofdeck, underside of the roof in the attic, for most attic applications. We will remove your old insulation, then spray foam is installed to the roofdeck. This allows for the attic to be used as storage space and future wiring can be installed as needed throughout the attic without competing with blown insulation to dig into. Spray foam also protects your HVAC system as ducts are then enclosed in a better environment for operation. Make sure to talk with your HVAC company regarding the different needs for homes that use spray foam insulation vs. fiberglass.

What is the difference between open and closed cell spray foam?

When it comes time to actually put the spray foam product in your home or commercial building structure, you must identify whether you will use 0.5 lb./cu. ft., open cell foam, or 2.0 lb./cu. ft. closed cell foam. This makes a big difference in cost, application methods, and performance.

With the open-cell vs. closed-cell issue, there are two major factors to understand and consider. The first is the nature of the foam. It is either open-cell foam, where the tiny cells of the foam are not completely closed. They are broken and air fills all of the “open” space inside the material. This makes the foam softer feeling than closed-cell foam.

Closed-cell foam differs in that all of its tiny foam cells are closed and packed together.

Density is measured by weighing one solid cubic foot of foam material

The advantages of closed-cell foam compared to open-cell foam include its strength, higher R-value, and its greater resistance to the leakage of air or water vapor. The disadvantage of the closed-cell foam is that it is denser, requires more material, and therefore, is more expensive. Even though it has a better R-value, typically the cost per R is still higher than open-cell foam. The choice of foam can also be based on the requirements for the other performance or application specific characteristics such as strength, vapor control, available space, location of installation, etc.

Both types of foam are commonly used in most building applications and the choice for which to use can depend on many of the factors discussed above. Some foams are inappropriate in specific applications. For example, you typically would not use open-cell foam below grade or in flotation applications where it could absorb water; this would neutralize its thermal performance because water is a poor insulator compared to air.

Closed cell spray foam is best used in ground floors, wine cellars, and masonry walls.

Open cell spray foam is best used on roofdecks, interior, and exterior walls.

What is an unvented attic system?

Unvented attics are beneficial for many reasons. First and most importantly by helping to seal the building system, which in return allows the central air conditioning system to operate more efficiently and effectively- removing moisture and reducing temperature. By placing the duct work in a climate controlled space, the dehumidified air from duct work and interior of home has less opportunity to create condensation as temperate difference of interior of home and attic space will not differ by large amounts. By sealing the building system you can prolong the life of your properly sized HVAC as well as prevent outside allergens and pollutants from entering your home. Homes with a properly sealed building system also benefit greatly on energy savings for life of the home.

Why do you remove the old insulation when upgrading your insulation?

Insulation that exists on the floor of the attic ceiling and any vapor retarder on the floor of the ceiling should be removed to allow for heat and moisture transfer through the ceiling. This is how the unvented attic space becomes indirectly conditioned space and the temperature and humidity in the attic can be controlled. By removing the existing insulation on the ceiling of the attic, you can be ensured that the unvented attic will provide the energy performance improvements intended by your insulation upgrade.

What happens to spray foam when it gets wet?

If a leak or roof damage occurs with open cell spray foam as your roof deck insulation material– you will instantly be able to identify the area and source of exterior roof damage. Upon repair, it is easily cut away and the leak or damaged area can be replaced. Upon repair and proper drying time, the area is efficiently able to be re-insulated with open cell spray foam.

We recommend closed cell spray foam on ground floor (crawl space) areas and multiple other applications to provide five full barriers of protection including: moisture, vapor, air, radiant, and as hurricane adhesive/ structural strength additive to your ground floor, outside decking, and other specialty applications.

Does spray foam support mold, mildew, or insect infestation?

No. Spray foam insulation can not support mold, mildew or insect growth or nesting

Does cellulose support mold, mildew or insect infestation?

Different brands and manufactures of cellulose insulation provide different products and results. The only cellulose material we install is environmentally friendly and does provide protection from mold, mildew and insect/ vermin infestation.

Which insulation products provide maximum energy savings?

Spray foam provides a complete air seal of your home system and provides maximum energy savings. In addition to energy savings a spray foam home is also a more healthy home due to reduction of allergens and outside pollutions.

How does spray foam impact other construction aspects?

Your insulation has an impact on your options for both remodeling and new construction projects.

- 2X6 walls are not required for higher R-value and energy savings.

- Spray foam is applied directly to the roof deck; therefore leaving the attic and area over garage usable for storage and/ or bonus rooms.

- The HVAC needs to be properly sized for spray foam and this reduces the cost of HVAC system by up to 30%.

- No ridge vents or venting soffits.

- Provides superior insulation for metal buildings and air port hangers vs. alternative insulation options.

- Using spray foam for both residential and commercial insulation uses eliminates other costly energy savings techniques and can help meet newest energy codes.

For maximum benefits in our humid climate, we recommend installing a dehumidifier with your system.

Can you spray foam around electrical wiring?

Yes. Spray foam is an excellent product to provide full insulation benefits even around electrical wiring.

How long does spray foam insulation last?

Spray foam insulation does not settle or lose R-value throughout the life of your home or office.

What factors impact pricing and how much will my insulation cost?

Insulation pays for itself over time with energy savings and lower utility bills. Different products have different needs and factors to consider upon installation. For spray foam both in new construction and remodeling applications these construction variables will all impact pricing:

- Roof pitch

- Accessibility

- Gables

- Kneewalls

- Size

- Weatherization of windows and doors

For a free on-site estimate and consultation call or click (850) 685-9709 or info@gulfcoastinsulation.com. Not ready for an on-site consultation- our staff can meet to discuss and review plans as well to provide accurate estimate.

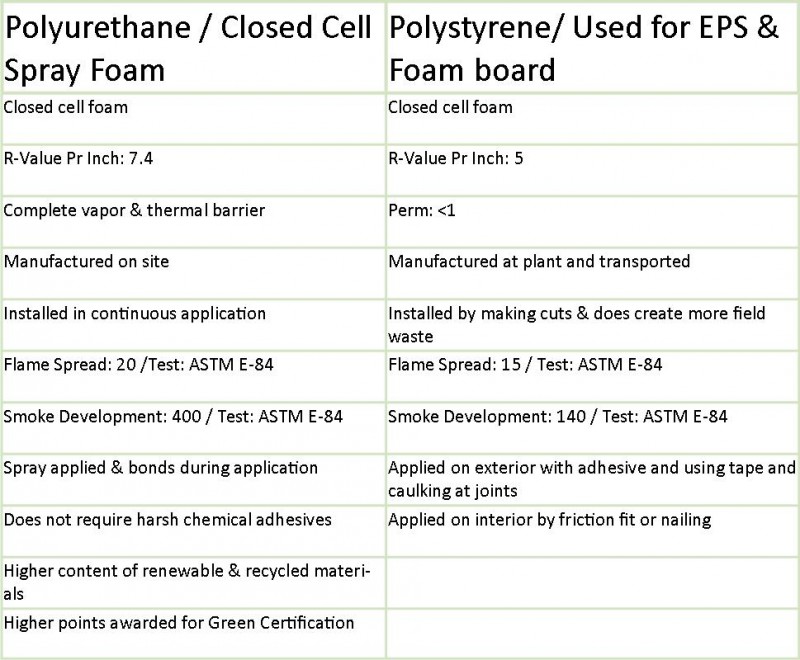

What is the difference between Polyurethane and Polystyrene Foam Insulation?

There are many differences between polyurethane and polystyrene foams. Aside from the material composition differences with these two foams, there are also large differences in how they provide insulation benefits. The side-by-side comparison uses closed cell spray foam for most comparable side-by-side of these two insulation materials. Exact specs will vary by manufacture; variance would not alter comparison results below.

How is GCI unique from other companies?

We are a local family owned & operated company committed to providing superior quality installation and products that enhance our customers’ quality of life by making their homes and businesses safer, quieter, more comfortable, and less expensive to operate.

Our Company At-A-Glance

- Our sales force includes only owners/ managing members and a reliable family member.

- We have the ability to use for detection and also verification infrared camera imaging to guarantee accurate results.

- All employees undergo background checks, DMV record reports, mandatory training as well as meeting Drug-free Workplace Program criteria.

- Our company is OSHA certified, ORCA certified & fully CCR registered. We are experienced in certified payroll reporting and adhere to all Department of Labor laws.

- Our installation equipment is completely customized and unique- built by us for our climate, area, products, and uses.

Our Daily Goal: Provide quality installation, service & dependably.

Done with this page, and still have a question? Simply contact GCI and a friendly and professional insulation specialist will assist you.